Media at the Touch of a Button

Krakatoa facilities fast iteration leading to optimization of cell culture media conveniently and sustainably. Get yours today at Nucleus Biologics.

Krakatoa Features

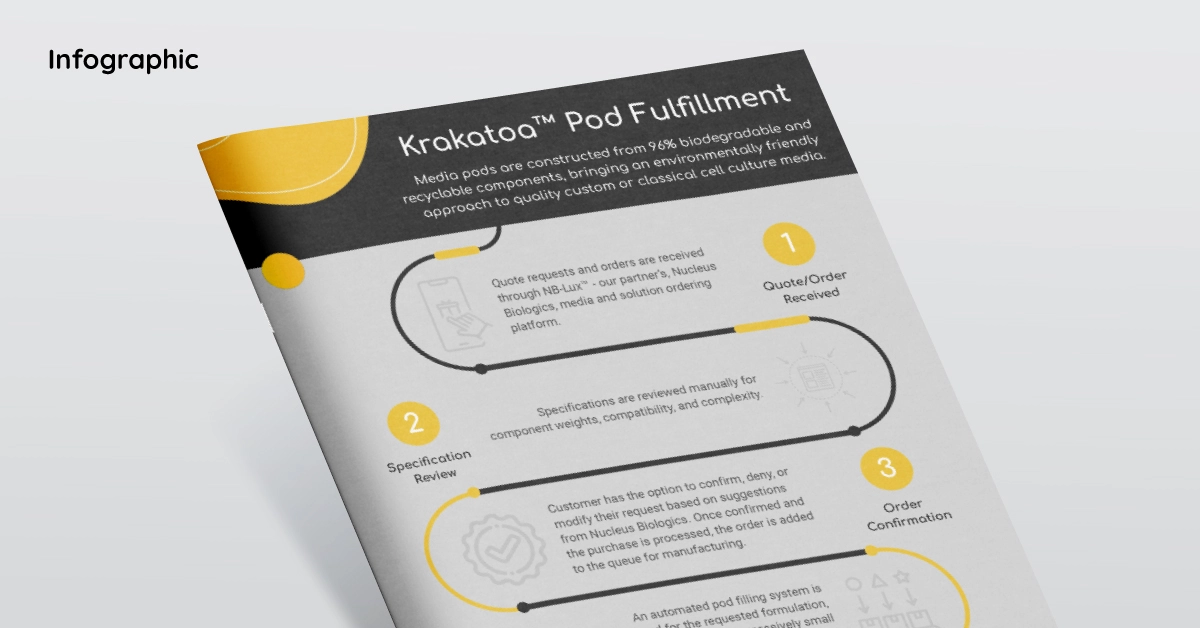

Integrated sensors

Define run specifications and ensure proper function

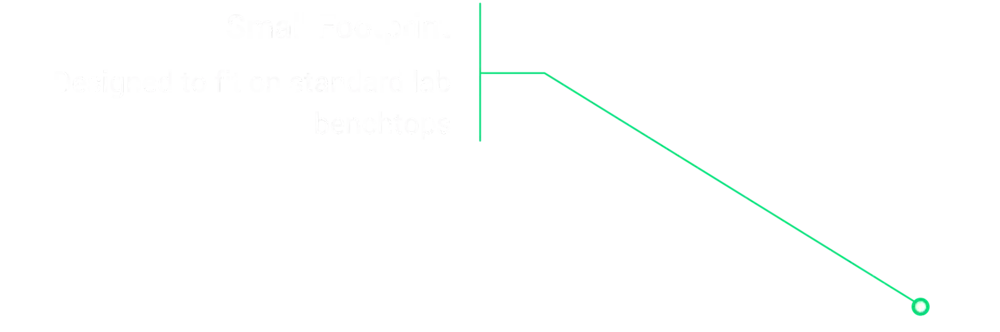

Intuitive touchscreen

Fully automated solubilization process and navigation for pod runs

Pod manifold

Insert biodegradable pod to solubilize and dispense 500 mL of media

Automated capping

Proprietary mechanism for bottle uncapping and capping

UV-C Sterilization

In-unit UV-C light sterilization process

Small footprint

Designed to fit on standard lab benchtops

Proven Functionality

Consistency of your cell media product is critical to the success of your development. Our protocols for pod filling and solubilization ensure media with equivalent quality and solubilized ingredient specifications as off-the-shelf media. In a direct comparison of Krakatoa mixed media and off-the-shelf media (DMEM/F-12 supplemented with 10% FBS), both media showed equivalent levels of amino acids when compared to a control specification.

Producing media sustainably is our goal to cure the planet, but producing quality media is a necessity to cure patients. Krakatoa media performs comparably to off-the-shelf media when analyzing cell proliferation and population doubling. In a comparison of off-the-shelf DMEM/F-12 supplemented with 10% FBS vs Krakatoa DMEM/F12 supplemented with 10% FBS on MSCs, our data shows equivalent cell confluence % from Day 0 through Day 6.

Krakatoa was evaluated for its capability in mixing media supplemented with large proteins. In our study, we manufactured CMRL media, a complex media formulation supplemented with insulin and transferrin. Media was tested for protein content after filtration and it showed comparable levels to the specification, proving that Krakatoa is capable of mixing, dispensing, and filtering advanced media.

Manufacture Greener Therapies

Roughly 5.5M tons of plastic waste per year is produced by our industry, taking centuries to decompose. Krakatoa, the world’s first benchtop media maker, was built so that together we can create a cleaner future, reducing waste and greenhouse gas emissions.

%

Reduction in total greenhouse gas emissions per 500 mL of media produced.

%

Reduction in transportation greenhouse gas emissions per 500 mL of media produced.

%

Reduction in end-of-life greenhouse gas emissions per 500 mL of media produced.

Make Your Cell Culture Science Sustainable

Download Our White Paper

Get our life cycle assessment white paper for free.

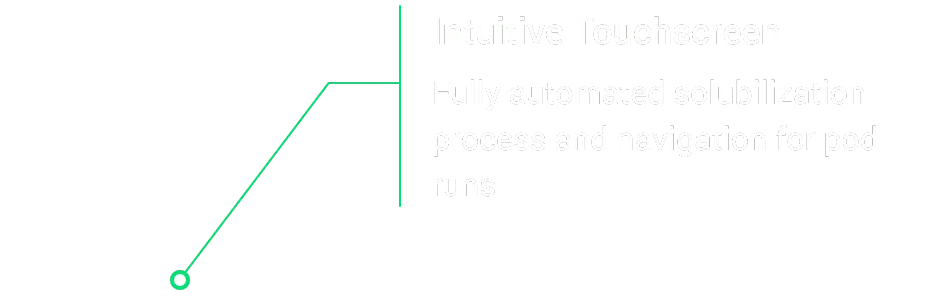

How It Works

Bottle and Pod Insertion

Solubilization and Sterilization

Media Dispensed

Pod Recycling

Every pod can be recycled through our recycling program— just seal the pod and place into the provided bags for shipping. We recommend no more than 10 per bag.

Changing the Way Cell Culture Media is Delivered

FAQ

Have a question? We’re here to help. If you don’t see your question, please contact us.

Can I purchase a Krakatoa™ directly from Stoic Bio?

Krakatoa is currently only available from our partner, Nucleus Biologics.

Does the Krakatoa™ device require cleaning?

Krakatoa runs an internal self-cleaning cycle automatically after every pod run. No input is required from the user to initiate this sequence. External cleaning may be performed periodically in accordance with the guidelines in the user manual.

What type of warranty does Krakatoa™ come with?

Krakatoa comes with a limited 12-month warranty.

Once I start a pod run, do I need to remain by the instrument during solubilization?

No. After inserting the pod and glass bottle, Krakatoa will run an automated pod run cycle and you do not need to be present for the solubilization stage of the pod run.

Resources and Downloads

Explore our latest resources to learn more about bringing sustainability to your research.

Contact Us

Complete the form and one of our specialists will contact you to discuss the many ways Stoic Bio can help you reduce your carbon footprint, accelerate your research, and lower costs.