The development process of cell therapies is extensive and requires a unique combination of expensive reagents and consumables, equipment, and experience to safely deliver a living drug to patients. Cell culture media and buffers customized and optimized to the growth characteristics of a specific cell type can positively impact critical aspects of development such as transduction efficiency, population doubling, yield, and maintenance of relevant phenotypes. This can greatly increase the therapeutic potency and expedite processes to accelerate time to market while reducing costs. Nucleus Biologics and Stoic Bio’s ecosystem, including the award-winning NB-AIR™ and Krakatoa™, can simplify the process of media design and customization, reduce cost, and facilitate sustainable science.

In this webinar, joined by collaborators from the University of Pennsylvania and the Center for Breakthrough Medicines, we will cover how high quality GMP products such as custom media and buffers can improve processes, optimize critical quality attributes, and change the paradigm of cell culture science from research and development to bioreactor scale production.

- How to expedite CAR-T process and what role custom media and reagent formulations play in this process

- How a custom designed formulation (NB-ROC™) was designed to increase transduction efficiency up to 3-fold over competing formulations

- How custom buffers can support efficient process development and improve product yields to support development

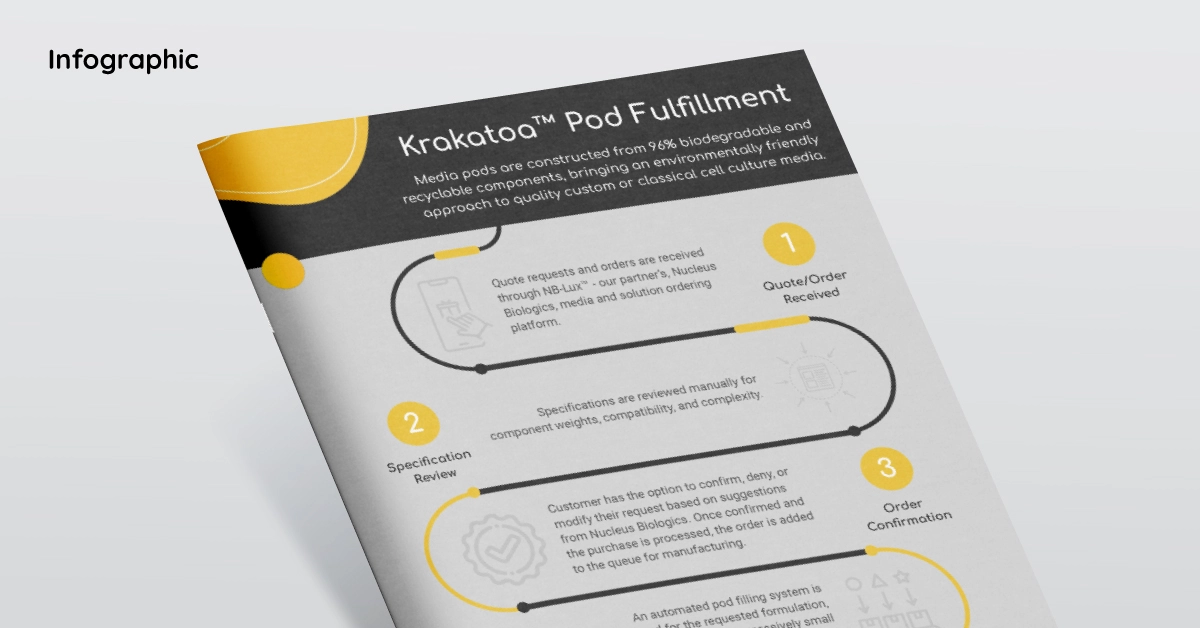

- How Krakatoa media manufacturing system and the Nucleus Biologics media design ecosystem can support faster iteration with reduced environmental impact